SKF Agri Hubs for slurry fertiliser discs boost farm productivity & profitability!

The new SKF Agri Hub for fertiliser injector discs has been specially engineered to boost farm productivity and profitability through increased performance and improved machine up-time while minimising the impact on the environment.

Under mounting pressure to increase yields while keeping input costs to a minimum, farmers look to OEMs for equipment that delivers ever-greater reliability, efficiency and performance. “This can be a challenge particularly for slurry fertiliser discs which operate under extremely harsh, corrosive conditions,” states SKF Key Accounts Manager – Agriculture, Charl Engelbrecht.

He explains that typically these machines incorporate conventional metallic hub assemblies to mount the cutting disc on to the slurry fertiliser injector machine. ”However, the low corrosion resistance and poor sealing performance of these conventional units often result in poor reliability and premature failure. The seasonal replacement of these units is an expensive exercise for farmers both in time and money.” Engelbrecht also points out that alongside increased warranty costs, premature failures hold the risk of damage to reputations and customer relationships for OEMs.

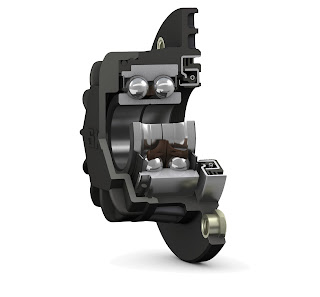

To overcome these challenges, SKF has specially designed and engineered the Agri Hub for slurry discs in the harsh, corrosive slurry injector environment. These independent fertiliser spreader disc attachments which are part of SKF’s successful and highly acclaimed Agri Hub portfolio feature a corrosion and water resistant glass fibre-reinforced polyamide housing for improved reliability and extended service life. The fact that this remarkable unit is greased for life means no re-lubrication is required, saving the farmer on time and lubrication costs.

2/…SKF Agri Hubs for slurry fertiliser

2/…SKF Agri Hubs for slurry fertiliser

SKF’s Mudblock seal and advanced hub bearing unit seals achieves excellent sealing performance, keeping the soil contaminant free. In addition, the Agri Hub is 50% lighter compared to a metallic unit of the same dimensions. Combined, these features result in a highly reliable, corrosion-resistant, cost-effective, maintenance-free unit that is also extremely easy to install.

For OEMs, the compact design and reduced weight of the Agri Hub offers a cost competitive alternative to conventional metallic hub assemblies while the unit’s optimised corrosion resistance can also reduce warranty costs.

Engelbrecht affirms that the Agri Hubs passed independent testing with flying colours. “In the tests which included a fertiliser spread field test as well as thermal aging and strength tests, the units demonstrated their superior productivity, impressive reliability and quality.” /Ends

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 15,000 distributor locations worldwide. Annual sales in 2015 were SEK 75 997 million and the number of employees was 46 635. www.skf.com

® SKF is a registered trademark of the SKF Group.

™ BeyondZero is a trademark of the SKF Group.

By: Sonia Laverick

Laverick Media Communications cc

Tel: +27 (0) 11 0400 818/ Fax: +27 (0) 86 671 6836

lavmedia@iafrica.com / www.laverickmedia.co.za

Comments

Post a Comment