There is a new industry standard in compressed air efficiency - Atlas Copco’s GA 22 to 37 VSDs

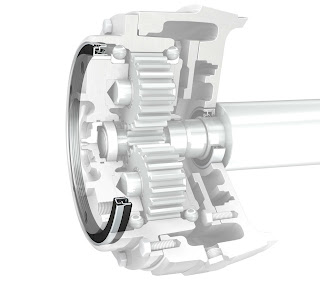

Delivering energy savings of up to 60% and an increase in Free Air Delivery (FAD) of up to 21%, (compared to fixed-speed models), Atlas Copco’s the new GA 22 – 37 VSDs (Variable Speed Drive) air compressor range is in an efficiency class of its own. Along with its ultra-efficiency, this exceptional air compressor range also raises the bar on performance, reliability and connectivity thanks to cutting-edge designs and innovative technologies. Atlas Copco revolutionised the air compressor industry with the introduction of VSD technology. This global first meant that compressors could do something they had never been able to do before - match their motor speed to fluctuating air demands, realising exceptional energy savings and reliability. Later, Atlas Copco brought improvements to this technology with the VSD+. Now Atlas Copco once again sets new standards in VSD performance with the launch of the new VSDs air compressor series. Atlas Copco Compressor Technique’s Business Line Manag...